The three drum dryer, also known as a triple-pass rotary drum dryer, is an improved version of the single-pass dryer. It consists of three coaxial drums, with the diameter gradually increasing from the inner to the outer drum, enhancing drying efficiency and thermal energy utilization.

It is suitable for drying materials with high moisture content, with the dried materials reaching a moisture level of 0.5%–1%. It is widely used in industries such as mining, building materials, and chemicals.

The drum has excellent thermal insulation properties, with thermal efficiency reaching 80% (compared to 35% for single-pass dryers), making it more energy-efficient.

Made with heat-resistant, wear-resistant alloy steel plates, the service life is 3-4 times longer than ordinary steel, significantly extending equipment lifespan.

The compact structure of the drying machine reduces the overall drum length to 30%–35% of a single-pass dryer, making it ideal for space-limited factories and reducing civil investment by 50%.

The structure is compact with an axial split design, making it easy to inspect and replace worn parts. The bolt connections are secure, ensuring easy maintenance.

The three drum dryer is suitable for drying materials such as yellow sand, foundry sand, river sand, artificial sand, quartz sand, mineral powder, fly ash, slag, gypsum, and clay.

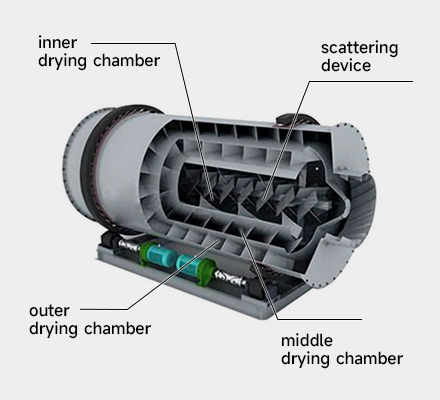

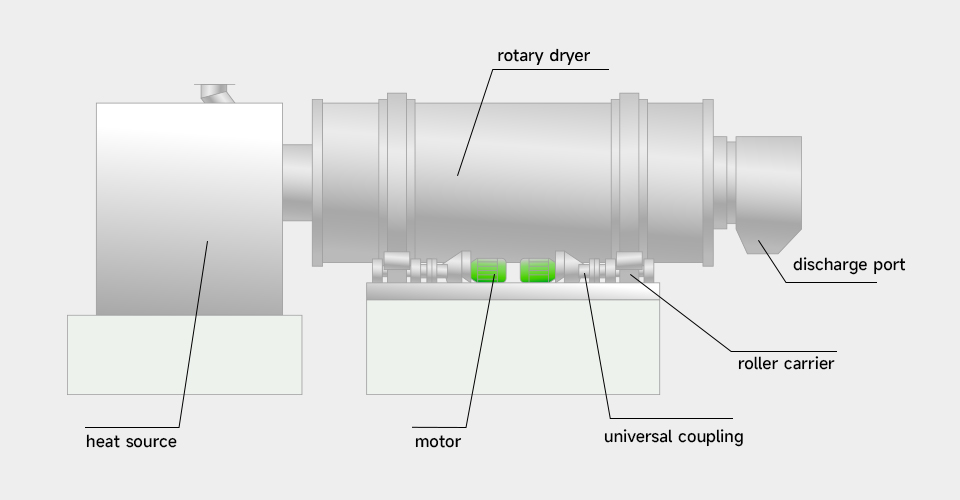

The three drum dryer consists of components such as the spring plate, rolling ring, bearing seat, motor, universal coupling, roller carrier, outer drying chamber, middle drying chamber, inner drying chamber, scattering device, and discharge port.

When the dryer is in operation, materials enter the inner drum via the feeding device for co-current drying. The lifting plates raise and scatter the materials, enabling efficient heat exchange. Then, the materials move to the middle drum for countercurrent drying, absorbing heat from both the inner and middle drums. Finally, the dried materials enter the outer drum, moving in a multi-loop pattern, and are quickly discharged by the hot air.

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | |

|---|---|---|---|---|---|

| Item/Unit/Model |

Φ2.5×7m

|

Φ2.7×7m

|

Φ3.0×7.0m

|

Φ3.2×7.0m

|

Φ3.6×8m

|

| Cylinder volume (m³) |

16.63

|

16.63

|

52.678

|

52.678

|

81.38

|

| Initial moisture of slag (%) |

10-12

|

10-12

|

10-12

|

10-12

|

10-12

|

| Final moisture of slag (%) |

1

|

1

|

1

|

1

|

1

|

| Initial moisture of yellow ground (%) |

8-10

|

8-10

|

8-10

|

8-10

|

8-10

|

| Final moisture of yellow ground (%) |

0.5-1

|

0.5-1

|

0.5-1

|

0.5-1

|

0.5-1

|

| Highest intake air temperature (℃) |

700-750℃

|

700-750℃

|

700-750℃

|

700-750℃

|

700-750℃

|

| Production capacity (t/h) |

Yellow sand: 25-30

Slag: 20-25 |

Yellow sand: 30-35

Slag: 25-30 |

Yellow sand: 35-40

Slag: 30-35 |

Yellow sand: 45-50

Slag: 35-40 |

Yellow sand: 65-70

Slag: 60-65 |

| Motor power (kW) |

7.5×2

|

11×2

|

7.5×4

|

7.5×4

|

15×4

|

| Reducer type |

XWD7-23-11W

|

XWD7-23-11W

|

XWD6-23-7.5KW

|

XWD6-23-7.5KW

|

XWD8-23-15KW

|

Want to know more parameters? Ask our experts

Fill in some minor details & we will take it from there. We look forward to a lasting partnership.