The sand dryer, also known as the sand rotary dryer, is an efficient industrial machine designed to dry granular materials with high moisture content. It is widely used in industries such as construction, glass, ceramics, and fertilizers.

This dryer uses advanced hot air technology, making it energy-efficient, easy to operate, and capable of drying sand evenly. It is an essential equipment in many industries, providing reliable moisture removal.

Advanced hot air drying technology quickly reduces moisture content, ensuring the final moisture level of sand is below 0.5%.

Key wear parts are made of high-strength manganese steel, which is 3-4 times more wear-resistant than standard steel, increasing service life and reducing maintenance costs.

The dryer supports fuels like natural gas, diesel, methane, and biomass pellets, ensuring efficient combustion and reduced drying costs.

The large drying space handles high volumes, while the variable frequency drive adjusts drum speed based on moisture and output.

The sand dryer is designed for drying a wide range of sand types, including river sand, sea sand, frac sand, lake sand, silica sand, quartz sand, yellow sand, and artificial sand.

These materials typically have high moisture content. Drying them helps improve their quality and storage stability, meeting the raw material requirements of construction and industrial sectors.

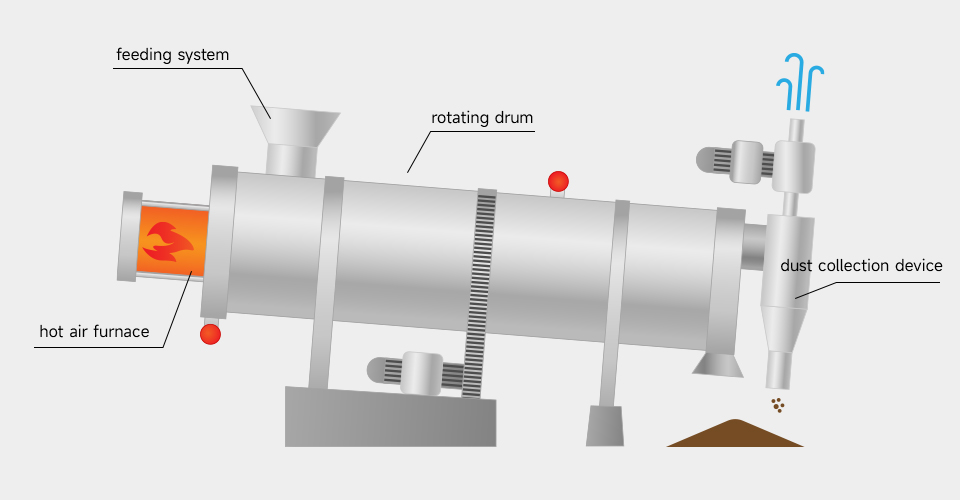

The sand dryer consists of several key components, including the rotating drum, hot air furnace, feeding system, discharge system, and dust collection device.

In operation, the wet sand is fed into the rotating drum, where hot air is introduced to heat and evaporate the moisture. The rotating drum ensures that the sand comes into full contact with the hot air, speeding up the moisture removal process.

The hot air is supplied by the hot air furnace, and as the sand continues to rotate, it gradually dries. The dried sand is then discharged through the system, while any dust or emissions are captured by the dust collection system.

| Model 1 | Model 2 | Model 3 | Model 4 | |

|---|---|---|---|---|

| Spec./m (Dia.×Length) |

Φ1.2×8.0

|

Φ2.2×12

|

Φ3.0×25

|

Φ3.6×28 |

| Shell Cubage (m³) |

9.0

|

45.6

|

176.6

|

285

|

| Capacity (t/h) |

1.9–2.4

|

9.7–12.2

|

37.7–47.1

|

60.8–76.0

|

| Highest Inlet Air Temperature (℃) |

700–800

|

700–800

|

700–800

|

700–800

|

| Main Motor (kW) |

7.5

|

22

|

75

|

160

|

| Weight (t) |

9

|

33.5

|

95

|

135

|

Want to know more parameters? Ask our experts

Fill in some minor details & we will take it from there. We look forward to a lasting partnership.