The rotary dryer is widely used in industries like mining, building materials, and fertilizers, especially for drying bulk materials such as coal, ore, clay, and fertilizers. Its key advantages are high processing capacity and consistent drying performance, handling varying moisture, shape, and particle size.

FTM Machinery offers two types of rotary dryers: direct rotary dryers and indirect rotary dryers. The indirect heating design prevents direct contact between the material and heating medium, making it more suitable for small and medium batch production.

Made with high-strength heavy-duty components (e.g., motors, gears, bearings), ensuring the dryer can endure continuous wear, corrosion, and harsh operating conditions in mineral processing.

From small units processing 1 ton per hour to large-scale units processing up to 76 tons per hour (over 11 feet in diameter), providing cost-effective drying solutions.

The LX multi-combination lifter plates increase the material’s contact area with hot air, enhancing drying efficiency and optimizing thermal energy use.

Equipped with advanced automation systems to monitor and control temperature and humidity in real-time, ensuring precise control over the final product moisture content.

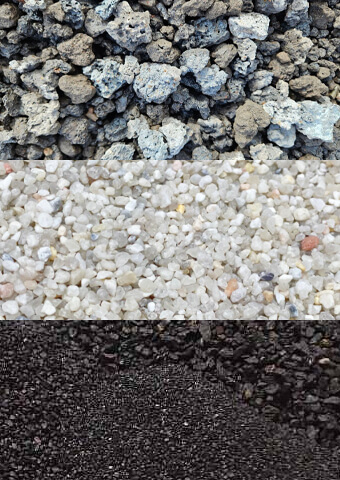

Rotary dryers are suitable for drying a wide range of materials, including:

Minerals: Limestone, gypsum, slag, bentonite, kaolin, clay, bauxite, etc.

Sand: River sand, sea sand, frac sand, quartz sand, etc.

Coal: Coal, coke, coal powder, coal slime, etc.

Fertilizers: Organic fertilizers, compound fertilizers, phosphate, nitrogen, potassium fertilizers, etc.

Waste & By-products: Sludge, tailings, fly ash, etc.

The rotary dryer is designed to handle granular, powdered, and lump materials, ensuring efficient and uniform drying.

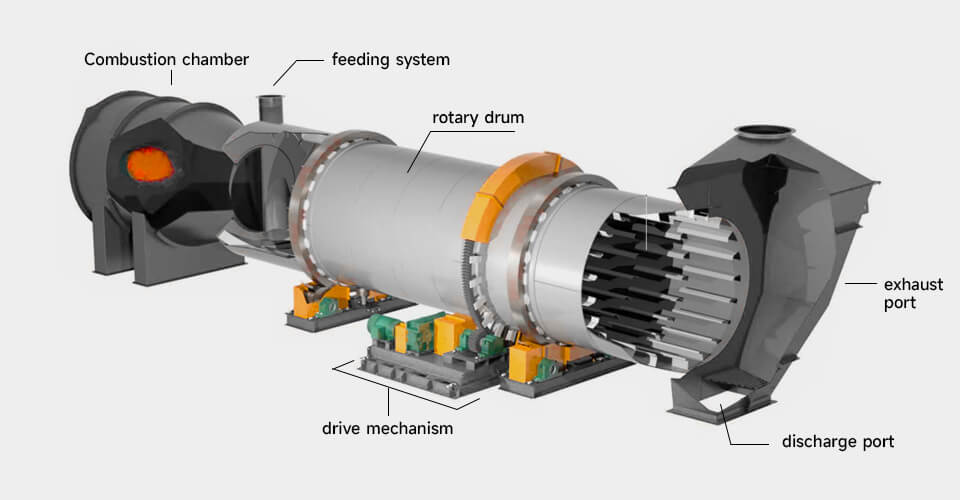

The rotary dryer consists of a rotating drum, heating system, drive mechanism, feeding system, discharge system, and exhaust system.

In operation, Wet material is fed into the inclined rotating drum, where it interacts with hot air in either counter-current or co-current flow. As the drum rotates, the material is constantly flipped, allowing for full contact between the hot air and the material, enabling moisture evaporation and heat exchange. The dried material is discharged through the discharge system.

Hot air is typically supplied by a burner, with various fuels (such as natural gas, coal, diesel, etc.) being used. The exhaust gases are either vented or recycled through the appropriate exhaust system.

Rotary Dryer

Indirect Heat Dryer

| Model 1 | Model 2 | Model 3 | |

|---|---|---|---|

| Spec./m (Dia.×Length) |

Φ1.2×8.0

|

Φ2.6×24

|

Φ3.6×28

|

| Shell Cubage (m³) |

9.0

|

127.4

|

285

|

| Capacity (t/h) |

1.9–2.4

|

27.2–34.0

|

60.8–76.0

|

| Highest Inlet Air Temperature (℃) |

700–800

|

700–800

|

700–800

|

| Main Motor (kW) |

7.5

|

55

|

160

|

| Weight (t) |

9

|

73

|

135

|

| Model 1 | Model 2 | Model 3 | |

|---|---|---|---|

| Shell diameter × shell Length Items |

Φ1.5×15m

|

Φ1.8×23m

|

Φ2.2×25m

|

| Shell cubage (m³) |

20.27

|

39.33

|

69.15

|

| Lifting blade form |

Lifting form

|

Lifting form

|

Lifting form

|

| Highest inlet air temperature(℃) |

850

|

850

|

850

|

Want to know more parameters? Ask our experts

Fill in some minor details & we will take it from there. We look forward to a lasting partnership.