The iron ore dryer is a high-efficiency rotary drum dryer designed for minerals. It effectively handles large amounts of ore, quickly removes moisture, and is a key tool in mining and metallurgy.

Suitable for both large mining companies and smaller processing plants, this drying machine delivers uniform results, enhancing the quality and market value of iron ore.

Advanced heat transfer and circulation technology ensures quick drying with minimal heat loss and reduced energy consumption.

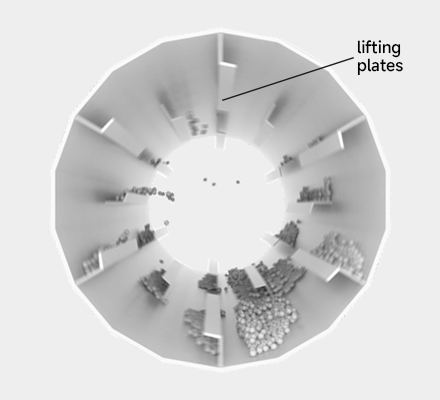

The uniquely designed rotary drum and lifting plates ensure even material distribution and optimal heat contact for consistent drying.

Supports various fuel types, including natural gas, coal, and diesel, allowing for cost-effective energy choices based on local resources.

Built with high-strength materials to withstand long-term, high-load operation, reducing wear and maintenance costs, and extending service life.

This iron ore drying machine is suitable for various minerals, including iron ore, iron ore pellets, copper ore, gold ore, manganese ore, molybdenum ore, metal concentrates, scrap iron, and tailings.

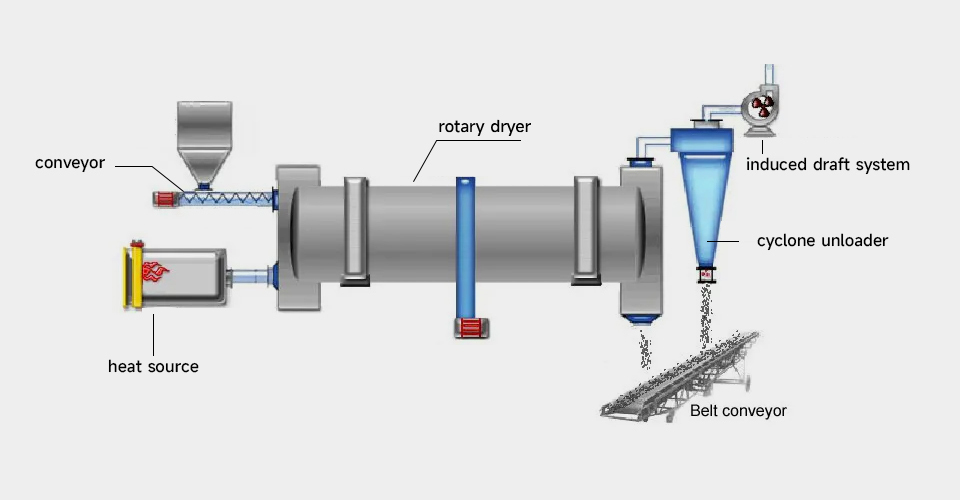

The system comprises a heat source, rotary drum, dust collector, induced draft fan, roller assembly, feeding and discharge units, and a transmission device.

Wet iron ore enters the drum’s higher end, and heat is introduced from the lower end. Inside, lifting plates scatter the ore for even heating. The ore moves downward under gravity, while the heat flows upward, allowing countercurrent contact. This process transfers heat to the ore, completing the drying process.

| Model 1 | Model 2 | Model 3 | Model 4 | |

|---|---|---|---|---|

| Spec./m (Dia.×Length) |

Φ1.5×14

|

Φ2.4×20

|

Φ3.0×25

|

Φ3.6×28

|

| Shell Cubage (m³) |

24.7

|

90.4

|

176.6

|

285

|

| Capacity (t/h) |

5.3–6.6

|

19.3–24.1

|

37.7–47.1

|

60.8–76.0

|

| Highest Inlet Air Temperature (℃) |

700–800

|

700–800

|

700–800

|

700–800

|

| Main Motor (kW) |

15

|

45

|

75

|

160

|

| Weight (t) |

19.7

|

54

|

95

|

135

|

Want to know more parameters? Ask our experts

Fill in some minor details & we will take it from there. We look forward to a lasting partnership.