The gypsum dryer (gypsum rotary dryer) is an efficient drying machine specifically designed for gypsum and related materials. Gypsum often contains high moisture during mining or production. Drying reduces the moisture content to optimal levels, improving its strength and stability for further processing.

Dried gypsum is widely used in the production of products like gypsum boards and gypsum powder, catering to the needs of the construction and decoration industries.

The fully sealed design minimizes heat loss, improves heat transfer, and maximizes gypsum resource utilization.

The newly designed feeding and discharging system effectively eliminates blockages, uneven flow, and backflow, improving overall production efficiency.

The gypsum dryer can adjust residence time, temperature, and airflow direction to optimize drying based on material properties and process needs.

The simple design and stable operation minimize downtime and maintenance costs, ideal for long, high-load operations.

The gypsum dryer is suitable for drying various gypsum materials, including desulfurized gypsum, pelletized gypsum, phosphogypsum, natural gypsum, building gypsum, gypsum powder, and more.

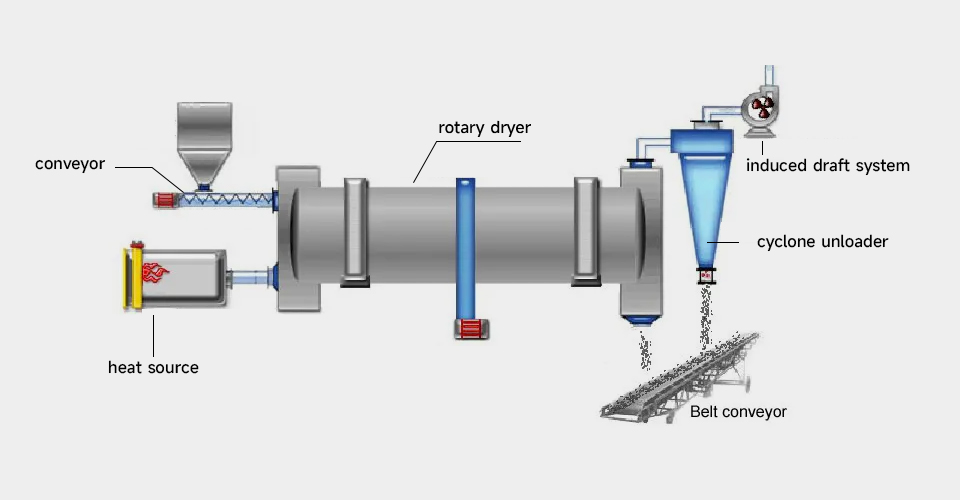

The complete gypsum drying system consists of a heat source, dispersing device, conveyor, rotary dryer, transmission system, dust collector, induced draft system, and control panel.

The heat source of the gypsum dryer comes from a combustion unit, using a co-current heating method. The material enters the inclined rotary drum through a feeding system and is pushed toward the rear by spiral lifting plates.

Due to rotation and gravity, the material is repeatedly flipped inside the drum, ensuring full contact with the hot air for efficient heat exchange. As the material flips, moisture gradually evaporates, achieving the desired drying effect.

| Model 1 | Model 2 | Model 3 | Model 4 | |

|---|---|---|---|---|

| Spec./m (Dia.×Length) |

Φ1.2×8.0

|

Φ1.8×12

|

Φ2.2×12

|

Φ2.6×24

|

| Shell Cubage (m³) |

9.0

|

30.5

|

45.6

|

127.4

|

| Capacity (t/h) |

1.9–2.4

|

6.5–8.1

|

9.7–12.2

|

27.2–34.0

|

| Highest Inlet Air Temperature (℃) |

700–800

|

700–800

|

700–800

|

700–800

|

| Main Motor (kW) |

7.5

|

18.5

|

22

|

55

|

| Weight (t) |

9

|

21.5

|

33.5

|

73

|

Want to know more parameters? Ask our experts

Fill in some minor details & we will take it from there. We look forward to a lasting partnership.