The fertilizer dryer is widely used in the drying process of various fertilizers, including organic fertilizers and compound fertilizers. It is especially suitable for drying fertilizers with specific temperature and particle size requirements in organic fertilizer production.

The rotary drum fertilizer dryer reduces fertilizer moisture from 70%–80% to 13% or lower, enhancing storage stability, processing efficiency, and reducing transportation costs.

The gentle reciprocating motion of the fertilizer drying machine reduces clumping. The advanced PLC system precisely controls temperature and humidity, preventing moisture buildup and ensuring high-quality end products.

Compared to traditional fertilizer dryers, this model has a larger load capacity, processing up to 76 tons of fertilizer per hour, meeting the needs of large-scale production.

The advanced heat recovery system and insulation design effectively reduce energy consumption, with thermal efficiency reaching 80%–90%, significantly lowering energy costs.

The equipment has a simple structure and high automation, making it easy to operate and maintain, ensuring stable and reliable production.

The fertilizer dryer is suitable for drying various types of fertilizers, including phosphate fertilizers, nitrogen fertilizers, potash fertilizers, manure fertilizers, compound fertilizers, and other organic fertilizers. It is effective for drying granular, powdered, or lump materials.

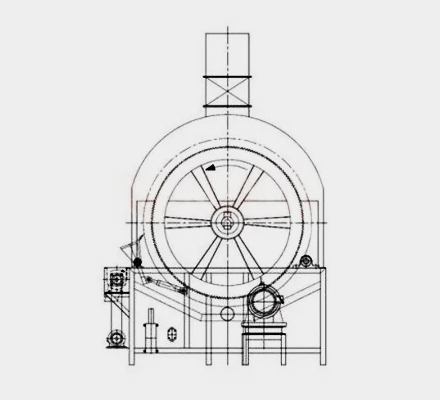

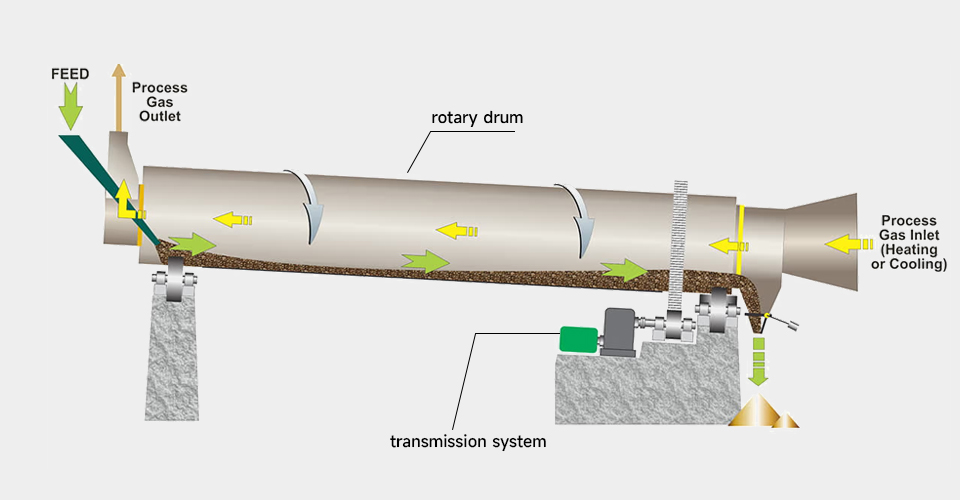

The fertilizer rotary drum dryer consists of several key components, including the rotating drum, lifting plates, transmission system, support devices, and sealing mechanisms.

In operation, wet fertilizer is fed into the inclined rotary drum through a conveyor. The material fully contacts hot air and is lifted by the lifting plates to enhance drying efficiency.

As the drum rotates, the dried fertilizer is discharged from the other end. Hot air can enter from either the feed side or the discharge side, depending on the drying requirements.

| Model 1 | Model 2 | Model 3 | Model 4 | Model 5 | |

|---|---|---|---|---|---|

| Spec./m (Dia.×Length) |

Φ1.5×12

|

Φ1.8×12

|

Φ2.2×12

|

Φ2.6×24

|

Φ3.6×28

|

| Shell Cubage (m³) |

21.2

|

30.5

|

45.6

|

127.4

|

285

|

| Capacity (t/h) |

4.5–5.7

|

6.5–8.1

|

9.7–12.2

|

27.2–34.0

|

60.8–76.0

|

| Highest Inlet Air Temperature (℃) |

700–800

|

700–800

|

700–800

|

700–800

|

700–800

|

| Main Motor (kW) |

15

|

18.5

|

22

|

55

|

160

|

| Weight (t) |

18.5

|

21.5

|

33.5

|

73

|

135

|

Want to know more parameters? Ask our experts

Fill in some minor details & we will take it from there. We look forward to a lasting partnership.