The coal dryer is an efficient and energy-saving drying machine, primarily used to dry wet coal in the coal industry. This equipment is widely used in industries such as power generation, metallurgy, and building materials.

It uses advanced drying technology to reduce the moisture content of coal from 20%–70% to below 13%, improving the coal’s heating value and combustion efficiency.

The four-stage low-temperature drying process reduces coal moisture to below 13%, greatly improving energy efficiency.

The innovative feeding and discharging system solves issues such as material blockage, uneven feeding, and drying of high-viscosity materials.

The dryer keeps the output temperature below 60°C, eliminating the need for additional cooling equipment, improving production efficiency, and reducing cooling costs.

The dryer has strong sealing and an efficient dust and noise reduction system, ensuring cleaner and more eco-friendly operation.

The coal dryer is suitable for drying various types of coal, including lignite, anthracite, coal slurry, raw coal, washed coal, coal powder, fine coal, and fly ash. It meets the drying needs for different types of coal products.

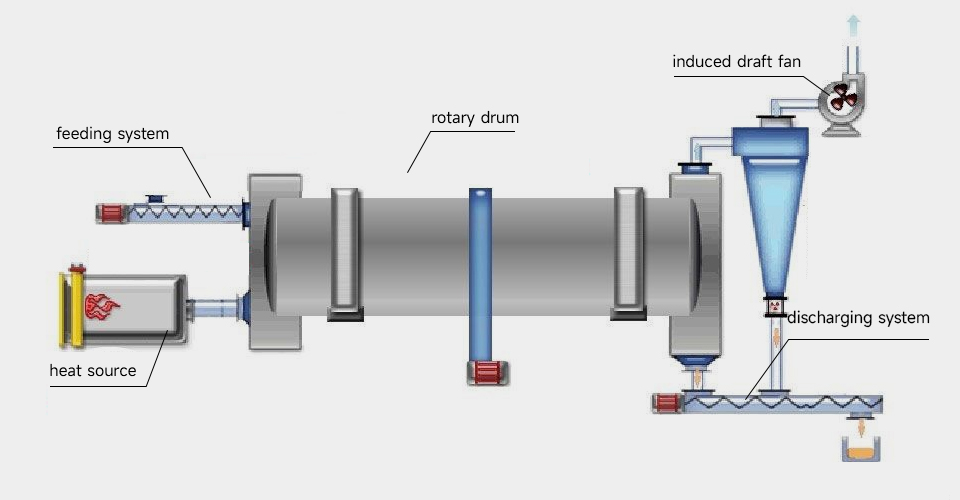

The coal dryer consists of several key components: the frame, heat source, feeding system, rotary drum, discharging system, induced draft fan, and control panel.

During operation, hot air enters the rotary drum through the heating system, exchanging heat and evaporating moisture from the wet coal.

The coal constantly tumbles inside the drum, increasing contact with the hot air and improving drying efficiency. Finally, the dried coal is discharged through the unloading system, with moisture effectively removed in an efficient and energy-saving process.

| Model 1 | Model 2 | Model 3 | Model 4 | |

|---|---|---|---|---|

| Spec./m (Dia.×Length) |

Φ1.2×10

|

Φ1.8×14

|

Φ2.6×24

|

Φ3.2×25

|

| Shell Cubage (m³) |

11.3

|

35.6

|

127.4

|

201

|

| Capacity (t/h) |

2.4–3.0

|

7.6–9.5

|

27.2–34.0

|

42.9–53.6

|

| Highest Inlet Air Temperature (℃) |

700–800

|

700–800

|

700–800

|

700–800

|

| Main Motor (kW) |

7.5

|

18.5

|

55

|

90

|

| Weight (t) |

11

|

23

|

73

|

110

|

Want to know more parameters? Ask our experts

Fill in some minor details & we will take it from there. We look forward to a lasting partnership.