Clay is a soil with low sand content and high plasticity, commonly used in ceramics, construction, and other industries. The clay dryer is a rotary drum dryer designed to effectively remove moisture from clay by controlling temperature and humidity, meeting the requirements for further processing.

It is widely used in industries such as ceramic manufacturing, brickworks, and other sectors that require drying of clay.

The drum is made of high-strength steel, offering excellent hardness and toughness, with superior wear resistance, enhancing the stability of the equipment.

The multi-lifting plate design and optimized internal structure promote even material dispersion and heat transfer, reducing wall adhesion and significantly improving drying efficiency.

Optimized roller structure and multiple lubrication methods reduce wear and the risk of shaft failure, extending service life and reducing maintenance intervals.

The dryer features good sealing and is equipped with an efficient dust removal system, creating a cleaner, safer work environment.

The clay dryer is ideal for drying materials like bentonite and kaolin, as well as a range of other industrial materials, including bauxite, quartz sand, activated white clay, red clay, montmorillonite, refractory clay, and illite clay.

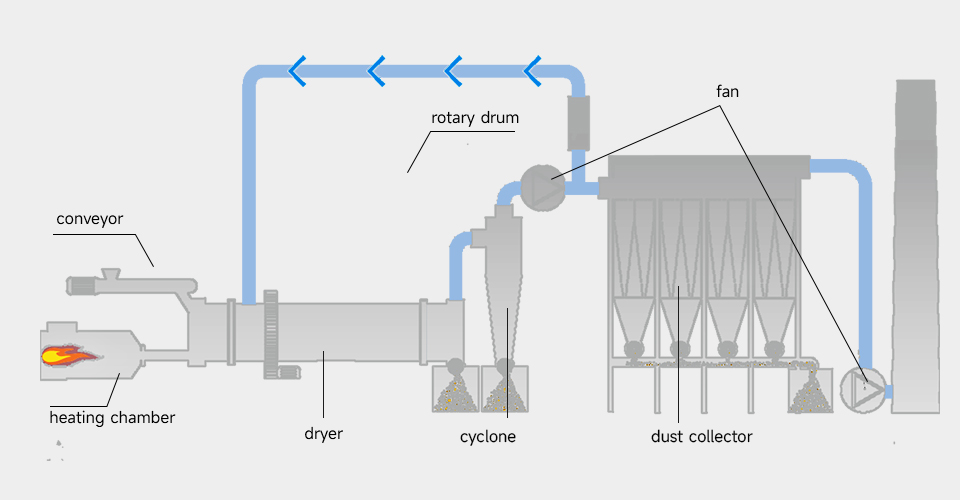

The clay drying line consists of a feeder, conveyor, burner, heating chamber, dryer, dust collector, fan, and discharge system.

Wet clay is fed into the inclined rotary drum through a conveyor. Hot air flows counter-current to the material, and as the drum rotates, the clay is lifted and turned by lifting plates, increasing contact with the hot air for more efficient drying.

The dried clay is then discharged through the unloading system. The hot exhaust air passes through a cyclone dust collector to remove impurities, and if necessary, further filtration is done by bag filters or water scrubbers.

| Model 1 | Model 2 | Model 3 | Model 4 | |

|---|---|---|---|---|

| Spec./m (Dia.×Length) |

Φ1.2×10

|

Φ1.5×14

|

Φ2.2×16

|

Φ3.0×25

|

| Shell Cubage (m³) |

11.3

|

24.7

|

60.8

|

176.6

|

| Capacity (t/h) |

2.4–3.0

|

5.3–6.6

|

13.0–16.2

|

37.7–47.1

|

| Highest Inlet Air Temperature (℃) |

700–800

|

700–800

|

700–800

|

700–800

|

| Main Motor (kW) |

7.5

|

15

|

22

|

75

|

| Weight (t) |

11

|

19.7

|

38

|

95

|

Want to know more parameters? Ask our experts

Fill in some minor details & we will take it from there. We look forward to a lasting partnership.